|

The Fracking Process FRACK UK considers below the nature of shale gas, and the exploitation method used to extract it. 1.1 Shale gas ‘Shale gas comprises methane recovered from mudrocks and shales which have previously been considered too impermeable (‘tight’) to allow economic recovery of gas’[1].

Shale gas on the other hand, which is where natural gas is effectively trapped within shale rock strata, is known as ‘unconventional gas’ or ‘shale gas’[2]. |

|

1.2 Hydraulic fracturing Whilst many perceive hydraulic fracturing as a relatively new technique, it was in fact first utilised in Oklahoma in 1949[3], and has been practised on land in the UK at over 200 sites during the last 30 to 40 years[4].

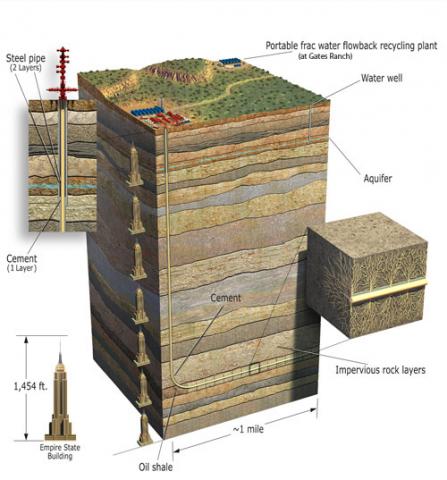

This technique involves drilling a vertical borehole to the depth where the shale formations exist, and using horizontal drilling techniques to then drill horizontally into the shale. During this process the well bore is cased and cemented in place.

The sand then becomes trapped within these fissures, thus holding them open and allowing the gas to flow back to the surface. This is known as ‘stimulation’ and detail of the technique is shown in the diagram above and in the video below. Fracturing usually needs to be re-visited once every 4-5 years to ensure continued gas production[9], but in the meantime all drilling rigs and associated equipment can be removed leaving very little plant on the site. Immediately after a successful fracture commonly 40-60% of the fracking fluid flows back up the well bore, and is known as ‘flowback fluid’. This is then recovered for subsequent treatment or in some cases re-use. For two videos on the fracking process, click here http://www.bloomberg.com/video/82563838-southwestern-operator-cutright-explains-fracking.html, and on the youtube video below. [1] British Geological Survey, Mineral planning Factsheet – Alternative fossil fuels (2011), page 4ww.bgs.ac.uk/downloads/start.cfm?id=2085 [2] see L. Magoon, Petroleum Systems of the United States (United States Government Printing Office, 1988), page 48 [3] see J.B. Clark, ‘A Hydraulic Process for Increasing the Productivity of Wells’ (1949) 1(1) Journal of Petroleum Technology 1-8; see Canadian Society for Unconventional Resources, Understanding Hydraulic Fracturing (2010), page 5 http://www.csur.com/sites/default/files/Hydr_Frac_FINAL_CSUR.pdf [4] C. Lowbridge, ‘Fracking confusion: How UK has been ‘fracked’ for decades’ (BBC News, 22 August 2013) http://www.bbc.co.uk/news/uk-england-23756320 [5] D. Rahm, ‘Regulating hydraulic fracturing in shale gas plays: the case of Texas’ (2011) 39(5) Energy Policy 2974, 2974; see also J. Curtis, ‘Fractured shale-gas systems’ (2002) 86(11) AAPG Bulletin 1921, 1937 [6] Royal Society, Shale Gas Extraction in the UK: a review of hydraulic fracturing (June 2012), http://royalsociety.org/uploadedFiles/Royal_Society_Content/policy/projects/shale-gas/2012-06-28-Shale-gas.pdf (“Royal Society Report”) [7] Royal Society Report, ibid., page 9 [8] Canadian Society for Unconventional Resources, Understanding Hydraulic Fracturing (2010), page 19 http://www.csur.com/images/CSUG_publications/CSUG_HydraulicFrac_Brochure.pdf [9] British Geological Survey, ibid., page 8 |

||