|

Environmental concerns In 2012 the European Commission financed a study into the potential risks of fracking within the EU. Entitled "Support to the identification of potential risks for the environment and human health arising from hydrocarbons operations involving hydraulic fracturing in Europe"[1] (“EU Environment Report”), the EU Environment Report endeavoured to consider risks ‘over and above those already addressed in conventional gas exploration and extraction’[2]. The report identified a plethora of risks associated with the fracking process, and in particular identified the following risks as ‘high’ (as opposed to moderate or low): |

|

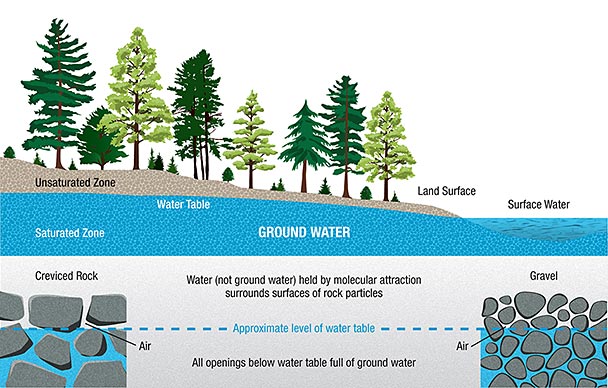

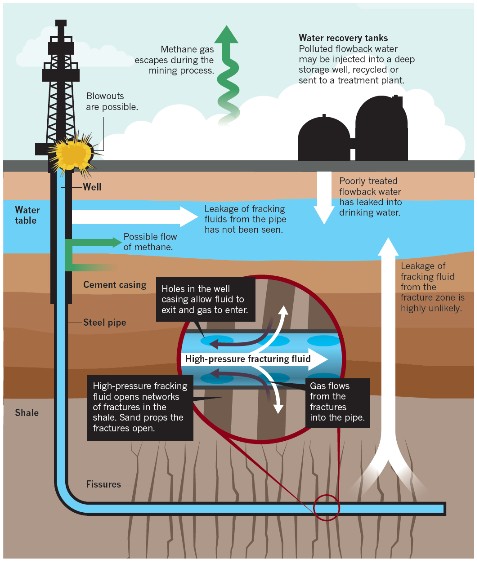

(i) groundwater contamination; (ii) surface water contamination; (iii) decrease in water resources; (iv) noise and traffic impacts; (v) release of pollutants to the air; and (vi) impact on bio-diversity. Before considering these in turn below, it is also believed that fracking can be responsible for minor earthquakes. However, the British Geological Survey ("BGS") considers that the risks associated with any earthquakes from fracking are low in view of the very minimal levels of seismic activity recorded, and as such the risk of any ‘structural damage is extremely unlikely’[3]. However, this is a particularly emotive issue for residents living in an area where fracking is taking place, and indeed new studies have pointed directly at fracking as being the cause of sustained and continuous earthquake activity in the USA[4]. It is also worth noting that on 27 November 2013 Water UK and UKOOG (the onshore operators' group) signed a Memorandum of Understanding to work together to identify and resolve risks around water and waste water including: (i) baseline monitoring requirements to assess impacts of onshore oil and gas development on the quality and quantity of local water resources; (ii) plans relating to site water management, especially water reuse, to improve understanding of local impacts; (iii) onshore oil and gas company development plans, including scenarios for expansion of exploration and development within a local area and what this means for short and long-term demand for water at specific locations; and (iv) the expected volumes and chemical and biological composition of waste water as well as preferred disposal routes. 1.1 Groundwater contamination Groundwater can be defined as ‘water held underground in the soil or in pores and crevices in rock’[5].

It has been argued in the USA that the fracking process itself, without any failure to the integrity of the well or poor handling of flowback fluids, has contaminated groundwater. These issues will be considered in turn. 1.1.1 The fracking process itself The contamination of groundwater by methane extracted during the ‘normal’ hydraulic fracturing process remains a hotly debated issue. Industry has argued that contamination in these circumstances is not proven, whereas residents (and their supporters) in sites around fracking activities in the USA have often demonstrated high methane concentrations in their drinking water[6]. Certain surveys conducted in the USA suggest contamination of shallow drinking water systems as a result of fracking activities[7]. A recent survey conducted by the US Environment Protection Agency (“EPA”) identified increased levels of methane in groundwater in close proximity to a fracking site in Wyoming. However, the EPA was unable to definitively state that the fracking process itself was to blame as these higher levels of methane may have been a naturally occurring phenomenon[8]. It is also worthy of note that in the Wyoming case, the well was drilled to a shallow depth of 372m, potentially increasing risks of vertical penetration of methane into the aquifer[9]. On this issue it is still being assessed whether ‘methane detected in water wells with the onset of drilling may also be mobilised by vibrations and pressure pulses associated with the drilling’[10]. Other reports have also been indecisive[11], and for now the case has not been proven[12]. In the USA, the root of the problem in associating fracking activities with increased methane levels in groundwater is that no record was taken of baseline methane levels in groundwater prior to fracking commencing. As a result, in the UK the BGS announced in 2011 it ‘is undertaking a new project to establish the baseline of methane levels in groundwater throughout the UK’[13]. The purpose of the project will be to determine baseline levels of methane in groundwater before shale gas activities commence in earnest ‘against which future environmental impacts can be assessed and appropriate management decisions taken’[14]. 1.1.2 Failure of well integrity

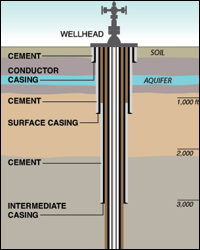

During the drilling and production phases, poor well design or construction can lead to natural gas leaking up, through and out of the bore into underground aquifers, thereby contaminating groundwater, most notably with methane. This can commonly occur when the cementing of the well casing has been ineffective. In this regard, normally the cement must ‘return to the surface’, meaning that from the point of fracturing below ground to the surface there must exist a continuous envelopment of cement around the well bore and casings within it, otherwise methane, other gases, fracking and flowback fluids can leak towards the surface and enter groundwater. It is worth noting that commonly these aquifers are situated several thousand feet above the shale formations where the fracking is taking place (see the uppermost diagram on this page), a reason industry has often used to highlight the safety to aquifers from the fracking process itself. However, this will not protect aquifers in the event of poor well design and construction. What is clear is that if the ‘well containment system’ (namely the well casing and cement) is not functioning correctly, methane, fracking and flowback fluids could leak into underground water systems. For this reason, where commonly two layers of cement and steel casings have historically been used to line a well in the USA, in the UK the Royal Society has stipulated that companies will use at least three layers of casings to minimise the risk of leaks. A recent report (March 2014), backed by the British Geological Survey, mentioned that some 6% of wells in Pennsylvania had suffered from internal or external well failures, something which highlights the risks involved in fracking if not properly regulated and controlled. See News link above for more detail.

1.1.3 Poor handling of flowback fluids In the USA flowback fluids which return to the surface after a hydraulic fracturing operation have been commonly held in open pits on the surface. Leakages from these pits have been proven to contaminate groundwater in the vicinity. According to the EPA: Detection of high concentrations of benzene, xylenes, gasoline range organics, diesel range organics, and total purgeable hydrocarbons in ground water samples from shallow monitoring wells near pits indicates that pits are a source of shallow ground water contamination in the area of investigation[16]. In the UK the Environment Agency (“EA”) has also analysed flowback fluids from Cuadrilla’s activities in Lancashire and found that they contained high levels of minerals dissolved from the rocks, such as chloride, sodium, iron and dissolved metals. They also contained very low levels of naturally radioactive minerals. All of the chemicals found are those which we would expect to find in shale rock[17]. Whilst in Cuadrilla's case these fluids were properly managed and did not leak into the environment, it is clear that flowback fluid must be carefully handled on the surface to prevent contamination. 1.2 Surface water

According to the Tyndall Centre report from November 2011 on the effects of shale gas on the environment and climate change[18] (“Tyndall Report”), surface water ‘is water collected above ground in streams, rivers, lakes and ponds’[19]. The Tyndall Report identified the following key areas where shale gas exploitation put surface water at risk[20]: (i) 'spillage, overflow, water ingress or leaching from cutting/mud pits’ – drill cuttings and mud used in the drilling process for lubrication, which are extracted to the surface and stored, are at risk from poor pit design and storm and flood waters; (ii) ‘spillage of concentrated fracturing fluids during transfer and final mixing operation’ - pipework or operator failure could cause this; (iii) ‘spillage of flowback fluid during transfer to storage’ – again, pipework or operator failure could cause this; (iv) ‘loss of containment of stored flowback fluid’ - tank storage or operator failure could cause this; (v) ‘spillage of flowback fluid during transfer from storage to tankers for transport’ – pipework or operator failure could cause this; (vi) ‘spillage of flowback fluid during transport to wastewater treatment works’ – an accident en route could potentially cause this, and just this sort of accident recently occurred in the USA[21]. However, it is acknowledged that these risks are ‘common to many industrial processes’[22] and have been properly managed in the UK in the past. 1.3 Decrease in Water Resources

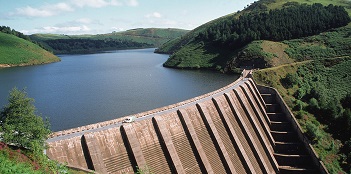

It is well documented that the fracturing process uses a considerable quantity of water. Indeed 99.5% of the fluid used in the fracking process is water in combination with sand[23]. The amount of water utilised ‘per frack’ will depend on the depth of the shale and its structural formation. The BGS acknowledges that shale gas production ‘uses up to several million litres of water a day’[24]. The Royal Society on the other hand stipulates that ‘the amount needed to operate a hydraulically fractured shale gas well for a decade may be the equivalent to the amount needed to water a golf course for a month’[25]. It is clear from academic opinion from the USA that very significant amounts of water are needed, commonly in the region of ‘up to 3 million gallons of water per treatment’[26]. Cuadrilla itself has estimated that it will use 1,600m3 per fracture operation[27]. The DECC, in its recent report entitled About Shale Gas and Hydraulic Fracturing (Fracking)[28](“DECC Shale Gas Report”) estimates between‘10,000 to 30,000m3 of water per well’[29]. In view of the amount of water required, the potential threat to water resources is a key legal consideration in the planning process for the extraction of shale gas. 1.4 Noise and traffic impacts

Due to the fact that ‘commonly multiple wells are drilled from a single pad’[30], a significant amount of equipment, including water and fracking fluids must be brought to and remain on site during the drilling phase of shale gas exploitation. A UNEP report in November 2012 on fracking[31] (“UNEP Report”) identifies that noise pollution is a common problem ‘primarily associated with drilling and fracking (which is a non-stop operation over several weeks) but also from truck transport’[32]. The same report estimates that ‘A single horizontal shale gas well will use between 11 and 34 million litres of water, roughly 360-1100 truck loads’[33]. The noise and traffic problems these deliveries have had in the USA are well documented. As one commentator put it ‘Sometimes western North Dakota seems like a truck jamboree featuring traffic-choked towns and semis barrelling down country roads’[34]. In the context of the UK’s A and B roads, the impact of traffic could be significant. 1.5 Release of pollutants to the air

The considerable use of heavy machinery during site preparation inevitably leads to high levels of exhaust emissions, ‘although these are not significantly different to emissions from any other similar construction activity’[35]. Drilling machinery is invariably powered by diesel generators, as is the machinery to pump fracking fluids into the well for fracturing purposes. As such diesel generators used during the drilling and fracturing stages will also result in exhaust emissions. However, in both cases these ‘diesel engine emissions do not pose a significant environmental or health risk’[36]. Of more environmental concern is the issue of methane returning to the surface during the ‘flowback’ of fracking fluids following a fracturing operation. In this regard, following fracturing ‘a proportion of the hydraulic fluid that has been injected into the well at high pressure returns to the surface and is known as flowback. Natural gas from the formation, predominantly methane, also returns with this fluid’[37]. Until this flow of methane is deemed to be of a quality which can be captured for sale, in the USA it is commonly flared, thus releasing carbon dioxide into the environment. Flaring does have an impact on air quality, and also leaves a noise and light footprint[38]. On the other hand, ‘cold venting’ of methane gas involves releasing the gas directly into the environment without flaring. This practice is generally not permitted for reasons of pollution and combustion risk on site. The United States, through the EPA, has issued regulations making it mandatory for operators to use ‘green completion technologies’ from 2015, instead of venting or flaring. These technologies capture the methane and other gases during flowback and store them, avoiding any methane emissions to air by venting or flaring. 1.6 Impact on biodiversity

The EU Environment Report defines biodiversity as ‘the range of species supported by the ecosystem(s) surrounding a shale gas development or area of shale gas development’[39]. The report sought to examine the risks to such biodiversity through the shale gas extraction process. The report concluded that during site preparation there is inevitably some loss of habitat, together with a risk of sedimentation of nearby water courses if sedimentary run-off risks during this phase are not properly controlled. However, overall the report considered these risks as ‘minimal’[40]. During the drilling phase there would be an increased level of noise, and disturbance through increased traffic, although again, these risks were deemed of ‘minor significance’[41]. During the hydraulic fracturing phase, the level of potential risk to biodiversity from leaks (both above and below ground) which could affect the local environment and in particular local water courses, was elevated to “moderate”. During the production phase, risk to biodiversity from on-site operational activities was considered low, although due to the nature of the industry and the potential for multiple sites in close proximity, the cumulative risk to biodiversity was considered ‘high’[42]. Of course, the level of the threat to biodiversity posed by fracking is open to debate, and certain commentators see the threat as more considerable than others[43]. It is a valid cause for concern, although again, the threats are similar to those posed by other industrial operations. For a diagram highlighting the potential risks from fracking, please see below:

For a video highlighting some of the environmental risks of fracking which have occurred in the USA, please click below. [1] see AEA, Support to the identification of potential risks for the environment and human health arising from hydrocarbons operations involving hydraulic fracturing in Europe (2012) http://ec.europa.eu/environment/integration/energy/pdf/fracking%20study.pdf (“EU Environment Report”) [2] EU Environment Report, ibid., page iv [3] see British Geological Survey, ‘Fracking and Earthquake Hazard’ http://earthquakes.bgs.ac.uk/research/earthquake_hazard_shale_gas.html [4] see Daily Mail, ‘Fracking did cause 109 earthquakes in Ohio, confirms scientists as opposition to controversial process grows’ (5 September 2013) http://www.dailymail.co.uk/news/article-2412048/Scientists-conclude-fracking-cause-109-minor-earthquakes-Ohio-started-just-weeks-controversial-practice-began-area.html [5] see Oxford Dictionaries, ‘Definition of groundwater in English’ http://oxforddictionaries.com/definition/english/groundwater [6] see GADCLuzerneCounty, ‘Light your water of fire from gas drilling, fracking’ (Youtube, 2011) https://www.youtube.com/watch?v=4LBjSXWQRV8 [7] see R. Jackson et al., ‘Increased stray gas abundance in a subset of drinking water wells near Marcellus shale gas extraction’ (PNAS, 3 June 2013), page 2 http://www.pnas.org/content/early/2013/06/19/1221635110.full.pdf+html [8] see EPA, Investigation of Groundwater contamination near Pavillion, Wyoming (December 2011), page 38 http://www2.epa.gov/sites/production/files/documents/EPA_ReportOnPavillion_Dec-8-2011.pdf [9] The Royal Society, ibid., page 12 [10] The Royal Society, ibid., page 12 [11] see S. Osbourne et al., ‘Methane contamination of drinking water accompanying gas-well drilling and hydraulic fracturing’ (14 April 2013) http://www.pnas.org/content/early/2011/05/02/1100682108.full.pdf+html [12] see R. Davies, ‘Methane contamination of drinking water caused by hydraulic fracturing remains unproven’ (2011) 108(43) PNAS 871 [13] British Geological Survey, ‘Press release: UK Shale Gas and Groundwater Methane’ (16 December 2011) http://www.bgs.ac.uk/news/NEWS/Groundwater%20Methane%20final.pdf [14] British Geological Survey [15] see C. Werth, ‘Fracking in the UK: Supporters look to avoid “reckless” US mistakes’ (The World, 19 March 2013) http://www.theworld.org/2013/03/fracking-in-the-uk-supporters-look-to-avoid-reckless-us-mistakes/ [16] EPA, ibid., 33 [17] Environment Agency, ‘Exploratory drilling in Lancashire’ http://www.environment-agency.gov.uk/business/topics/134511.aspx [18] Tyndall Centre for Climate Change Research, Shale Gas: an updated assessment of environmental and climate change impacts (November 2011), http://www.tyndall.ac.uk/sites/default/files/coop_shale_gas_report_update_v3.10.pdf (“Tyndall Report”) [19] Tyndall Report, ibid., page 88 [20] Tyndall Report, ibid, page 88 [21] see L. Todd, ‘Overturned semitrailer, fracking fluid spill shut down busy Caster intersection’ (Star Tribune, 30 May 2013) http://trib.com/news/local/casper/overturned-semitrailer-fracking-fluid-spill-shut-down-busy-casper-intersection/article_002d4785-ace1-5741-8726-5eadf0b729bc.html [22] The Royal Society, ibid., page 20 [23] see M. Fischetti, ‘The Drillers are coming’ (July 2010) Scientific American 82, 84 [24] British Geological Survey, ibid, page 11 [25] The Royal Society, ibid, page 20 [26] D. Soeder et al., ‘Water Resources and the Production of natural gas from the Marcellus Shale’ (USGS Factsheet 2009), page 4 http://pubs.usgs.gov/fs/2009/3032/pdf/FS2009-3032.pdf [27] see P. Richards et al., ibid. page 11 [28] Department of Energy and Climate Change, About Shale Gas and Hydraulic Fracturing (Fracking) (30 July 2013) https://www.gov.uk/government/publications/about-shale-gas-and-hydraulic-fracturing-fracking/about-shale-gas-and-hydraulic-fracturing-fracking (“DECC Shale Gas Report”) [29] DECC Shale Gas Report, ibid., para 3.4 [30] Canadian Society for Unconventional Resources, ibid., page 16 [31] UNEP, Gas Fracking: Can we safely squeeze the rocks ? (November 2012) http://www.unep.org/pdf/UNEP-GEAS_NOV_2012.pdf (“UNEP Report”) [32] UNEP Report, ibid., page 7 [33] UNEP Report, ibid., page 8 [34] E. Richards, ‘The New Oil Landscape’ (National Geographic, September 2013) http://ngm.nationalgeographic.com/2013/03/bakken-shale-oil/richards-photography#/12-truck-traffic-choked-roads-670.jpg [35] see EU Environment Report, ibid., page 30 [36] see EU Environment Report, ibid., page 30 [37] Tyndall Report, ibid., page 56 [38] Tyndall Report, page 56 [39] see EU Environment Report, ibid., page 32 [40] see EU Environment Report, ibid., page 32 [41] see EU Environment Report, ibid., page 39 [42] see EU Environment Report, ibid., page 65 [43] see J. Gillen et al., ‘Hydraulic Fracturing Threats to Species with restricted geographical ranges in the Eastern United States’ (2012) 14(4) Environmental Practice 320 |

||